Two years after unveiling one of the aviation industry’s most comprehensive technology demonstrator programmes for a more sustainable future of flight, CFM International has completed more than 100 tests as part of its Revolutionary Innovation for Sustainable Engines (RISE) programme. Learn more about the history of innovation leading to RISE.

In 1941, the United States government asked GE to develop the first American jet engine. Allied defense, industrial collaboration, technological advancement, and economic growth were at stake. GE delivered the very next year.

Now, more than 80 years later, GE Aerospace finds itself at the cusp of another era-defining moment. With climate change impacting communities and economies around the world, the aerospace industry is in the midst of what feels to some like a seismic shift.

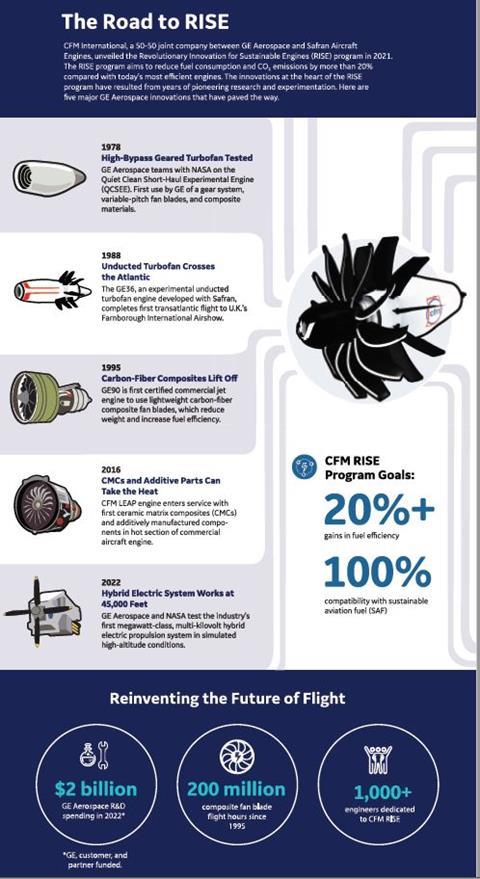

To meet this challenge, CFM International, a 50-50 joint company between GE Aerospace and Safran Aircraft Engines, unveiled the Revolutionary Innovation for Sustainable Engine (RISE) program in 2021. The CFM RISE program aims to reduce fuel consumption and carbon dioxide emissions by more than 20% compared with today’s most efficient aircraft engines. Improved engine efficiency is key to helping the aviation industry achieve a larger target: net zero CO2 emissions by 2050.

In terms of sustainability, it’s a bold goal. But as Arjan Hegeman, GE Aerospace’s general manager of advanced technology, recently put it: “History will judge us to be on the right side of the fence.”

Notwithstanding the urgency of the moment, the groundwork laid for the CFM RISE program has been decades in the making. Indeed, the innovations at the heart of the program — open-fan architecture, carbon-fiber composites, ceramic matrix composites, and additive technology — are the result of years of painstaking research, testing, and validation.

See our timeline below about the technologies behind the RISE program: