Engine makers need to focus more on the quality of their products, according to the chief executive of AirAsia parent Capital A.

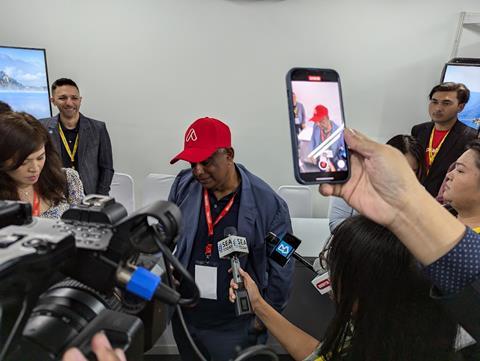

Speaking at the Bali air show on 18 September, Tony Fernandes highlighted the challenges airlines face with engines and expressed the view that manufacturers are too focused on profitability.

“Supply chain is a big problem,” says Fernandes. “It’s a big problem and it’s not something that we can control. I would say very strongly that [OEMs] are making record profits, but they have to reinvest those profits into giving us a better product.”

AirAsia Group’s fleet of Airbus A320neo-family jets are powered by Leap-1A engines supplied by the CFM International joint venture between GE Aerospace and Safran.

Despite slower Leap deliveries in the second quarter, GE Aerospace saw its first-half operating profit jump 31% to $3.4 billion, while Safran saw operating profit rise 22% to €1.28 billion ($1.39 billion) in the same period.

Fernandes takes specific issue with length of time required for engine shop visits. “Engines used to take ninety days to turn around, but now it’s as long as 450 days,” he says.

“It’s really time for OEMs to invest more in their product, because airlines get the blame… for a shortage of spare parts. Customers are frustrated.”

Asked if AirAsia is disappointed with the reliability of new-generation engines, Fernandes notes that new technologies always having teething issues. He adds that the coronavirus pandemic also had an impact on the supply chain.

“But I do think that OEMs need to invest more,” he adds. ”There is too much emphasis on short-term profitability, they need to look after their customers better.”

Despite all this, he says that the airline has a “fantastic relationship” with GE and CFM, and that the “engines are performing pretty well.”