Marion Chambre describes experiencing live the first ground-test run of the LEAP engine as one of the highlights of her career. Eleven years on, the Safran Aircraft Engines engineer has a crucial role on CFM’s RISE demonstration programme

“It was like the Apollo 13 movie when they wait for the crew to communicate after they re-enter the Earth’s atmosphere.” That is how Marion Chambre describes the tension among the assembled GE Aerospace and Safran Aircraft Engines employees waiting to witness the firing up of the first LEAP engine on the former’s test rig at Peebles, Ohio, almost exactly 11 years ago.

“It is the best memory of my working life so far,” enthuses the French engineer, who is the CFM RISE low-pressure turbine (LPT) systems cooperation leader at Safran Aircraft Engines at its main campus in Villaroche, near Paris. “I can still remember the silence just before the engine started into life. Everyone in the room was so emotional and proud to see that great achievement, the culmination of work started a decade earlier – two teams united in one incredible bigger team.”

For much of her 13-year career with Safran Aircraft Engines, Chambre has been involved in CFM programmes. After completing a postgraduate masters in astronautics and space engineering from the UK’s Cranfield University, she joined the CFM partner company as a mechanical engineer on the LEAP engine development, which led to her being part of the first engine to test (FETT) audience in September 2013.

Chambre – who grew up in Châtellerault and whose first degree was in aeronautics and mechanics from the ISAE-ENSMA school near Poitiers in western France – has been involved for the past three years on the Revolutionary Innovation for Sustainable Engines or RISE programme. Her current role, she says, places her “directly at the heart of CFM”, coordinating, preparing, and delivering work packages that involve teams from both sides of the Atlantic.

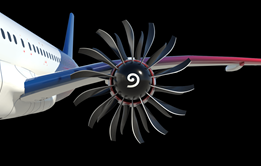

She appreciates having a job that constantly pushes her professionally, describing the technical challenges of the RISE programme – launched by CFM in 2021 to accelerate the development of new propulsion technologies that will pave the way for the next generation of more sustainable aircraft – as a “blessing for engineers like me”.

“On the LPT, on top of dealing with high temperatures and significant gas load on the flowpath, we are experiencing the sort of speeds that you normally experience with high-pressure turbines, twice those of most LPTs,” she says. “That requires new seal technologies, materials, and architectures.”

The RISE turbine system – from the initial design to the testing phase – is very much a joint effort between both CFM partner companies, says Chambre, who adds: “It requires close links between all the teams, whether they are in France, the US, or Italy (where GE Aerospace subsidiary Avio Aero is based). As when any family gets together, there are sometimes disagreements, but we always manage to work these out through discussion and our strong relationships.”

Often competition leads to even deeper cooperation, such as when engineering teams from both GE Aerospace and Safran Aircraft Engines are working on what are effectively rival potential solutions to a requirement. “It means we must work hand-in-hand to make the best technology choices and integrate them,” she says. “Each team is pushed by the other to build the best product.”

Working on CFM initiatives such as LEAP and RISE, says Chambre, means that she has had the opportunity not only to learn best practices within the wider Safran culture, but also to have the experience of collaborating with colleagues from GE Aerospace. “It is the CFM spirit to share ideas, legacies, and methodologies to create the best product together,” she says.

Her current role on the RISE programme is a “tremendous opportunity to address climate change challenges and take another significant step towards more sustainable air transport”, she maintains. “Developing technologies that will contribute to the future of aviation is more than a passion – it’s a responsibility for my generation of engineers. I am proud to contribute to something that will change not only our industry but society at large.”

CFM International at 50

It was a marriage many said could not last and some tried to stop happening. But like many unlikely unions, the 1974 coming together of General Electric and Snecma (today, GE Aerospace and Safran Aircraft Engines) has endured and prospered. Fifty years on, their creation, CFM International, is the most ...

- 1

- 2

- 3

- 4

- 5

Currently

reading

Currently

reading

CFM International at 50: Great minds

- 7

- 8

- 9

- 10