Mathieu Gaillot says he has been on a ‘remarkable journey’ with CFM since he was chosen for a role on the newly launched LEAP programme as a graduate engineering recruit to Safran Aircraft Engines. Fifteen years later, focused on CFM RISE, he is still thriving on the ‘collaborative spirit of the team’

Mathieu Gaillot describes his experience of working on CFM projects for all but four of his 15 years as an engineer with Safran Aircraft Engines as “a remarkable journey of discovery and achievement”, characterized by “a rich collaborative culture”.

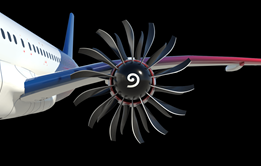

His career so far has taken him from being employed as a recent graduate on the aerodynamics of the inlet and nozzle on the preliminary LEAP-1A and LEAP-1B engines to his current job leading the team responsible for designing the aero-acoustic elements of the Open Fan on the RISE (Revolutionary Innovation for Sustainable Engines) programme.

It is a position that sees him work daily with GE Aerospace colleagues as well as airframers. “Every day presents new challenges and discoveries, fostering an environment of continuous learning and innovation,” he says. “I thrive on the collaborative spirit within our team as we collectively tackle the complexities of aircraft integration.”

In addition, he manages the aero-acoustic maturation roadmap, which involves engaging with partners in academia and research laboratories. These include the wind tunnels run by French agency ONERA and German-Dutch body DNW that are crucial to finessing the technologies around the Open Fan design.

Gaillot’s career with Safran Aircraft Engines began in 2009, just after he had graduated from the ISAE-ENSMA school in Poitiers, specialising in energetics. It was an exciting time as CFM partners GE Aviation (as it then was) and Safran Aircraft Engines had one year earlier at the Farnborough air show launched what they were calling the LEAP-X engine.

With both companies devoting extensive engineering resources to what would become the successor to the CFM56, Gaillot found himself “immediately immersed in the CFM product line”, with a role initially focused on installation aerodynamics. He was responsible for inlet and nozzle designs and their integration into what would shortly become the LEAP-1A (for the Airbus A320neo family), and the LEAP-1B (for the Boeing 737 MAX).

The job not only “sharpened my technical skills” but gave Gaillot the opportunity to travel to the US for the first time for nozzle testing near Minneapolis. “The trip was particularly memorable as it marked the first face-to-face meeting with my colleagues from GE after nearly two years of virtual collaboration,” he recalls.

Gaillot, who is based at Safran Aircraft Engines’ main site at Villaroche, France, moved to LEAP-1B fan aerodynamics during the engine’s development stage, with his focus changing from integration to module design. From 2013 to 2016 he was involved in finalising the fan and booster designs and preparing them for development tests and certification.

One of the most “thrilling moments” of this point of his career came at the LEAP-1B’s FETT (first engine to test) in Villaroche. “Standing in the test room, I could feel the palpable tension as our team awaited the engine’s first start,” he recalls. “The moment the engine began to run was electrifying, uniting the entire CFM team in a shared sense of accomplishment and joy.”

Another time that stands out was when he was involved in LEAP-1B flight thrust determination work with Boeing, as part of a 15-strong team. For one-and-a-half years, he took part in “deep technical discussions” with the airframer every week, and attended several workshops in Cincinnati and Seattle, as well as tests at GE Aerospace’s Peebles, Ohio outdoor test facility.

“We were calculating, step by step, one of the most important parameters of any aircraft engine: thrust,” he says. “I remember this as one of the best topics I worked on in my career. What a time it was when we arrived at the end of the final audit that validated the approach we had proposed.”

After a three-year gap working on another Safran Aircraft Engines programme, Gaillot says he was “eager to return to my roots at CFM”. He was offered a job as integration manager on the CFM RISE systems team where he managed the preliminary design of the Open Fan nacelle. “This role meant I could pursue my passion for aerodynamics and systems integration, allowing me to play a pivotal part in the evolution of an innovative product,” he says.

A highlight of this phase of his career was leading the first Open Fan sub-scale rig demonstrator project, known as EcoEngine. The effort aimed to mature the Open Fan aero-acoustic design through wind-tunnel testing at ONERA. “Witnessing the EcoEngine come to life on 5 January 2023 was a profound experience for me, akin to the LEAP-1B FETT,” he says. “The thrill of seeing a project I led take shape was testament to the innovative spirit fostered within CFM.”

Gaillot says one of the best aspects of working for the CFM joint venture is the “opportunity to learn new things every day alongside amazing colleagues”. He adds: “The strength of CFM lies in the collaborative spirit of both partners, where diverse ideas are not only shared but refined together, leading to even better solutions.”

He maintains the partnership has fostered transatlantic friendships that extend beyond the workplace. “I still stay in touch with my first counterparts, maintaining connections that have lasted more than a decade. These relationships are a testament to the supportive and collegial environment that CFM promotes,” he says.

Being part of CFM has given him “opportunities, to grow, innovate, and collaborate”, he says. “From my early days in aerodynamics to leading groundbreaking projects, each experience has enriched my career and deepened my commitment to decarbonizing aviation.”

CFM International at 50

It was a marriage many said could not last and some tried to stop happening. But like many unlikely unions, the 1974 coming together of General Electric and Snecma (today, GE Aerospace and Safran Aircraft Engines) has endured and prospered. Fifty years on, their creation, CFM International, is the most ...

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

Currently

reading

Currently

reading

CFM International at 50: Transatlantic bonds